|

|

|

home > Industry News

Optimistic about polyester elastic fiber development forecast

Among many functional fibers, elastic fiber plays an irreplaceable role in comfort and shape retention because it can give good contact feeling to the human body. Therefore, endowing certain flexibility to textile fabrics has become an inevitable development tendency for textiles for apparels. In 1959, after DuPont introduced large-scale Lycra products, elastic fibers caused widespread concern. In the 1990s, with the expansion of the function of the following link (such as the development of spandex core-spun technology), spandex stretch fabrics began a new round of production climax. The use of spandex increased rapidly, and many large foreign companies have also developed their own unique spandex production technology, greatly improving the quality of its products, such as Taekwang from South Korea and Hyosung etc. At the same time, the melt-spinning technology also made breakthrough progress. Due to its low investment cost and environmental advantages, it has developed rapidly. At present, the global spandex capacity has reached 1.12 million tons, including Hyosung from South Korea, Ruyi from China (Invista acquired spandex business from DuPont in 2004, and this business has been acquired by Ruyi), and Huafon, which ranked the top three in view of capacity. Spandex is the textile fiber with the best elastic elongation and elastic recovery rate by now, which has been favored by people since its emergence. However, with the development of the textile industry, various drawbacks of spandex fabrics have also been amplified, such as the relatively large deficiencies in color fastness, anti-aging and other aspects. In order to effectively solve these drawbacks of spandex and further meet the market requirements, people put their eyes on the polyester elastic fiber. PBT and PTT both belonged to polyester series have begun attracting attention from people, and their structure is similar to that of PET, but the alkane chain of the dihydric alcohol is longer. After the carbon chain of the dihydric alcohol increased, the flexibility of the molecular chain of the polyester is enhanced, and the structural characteristics of the "segment" of the hard segment and the soft segment in the molecular chain are more and more apparent; therefore, the elasticity of the polymer or fiber is enhanced, but the elasticity of these stretch fiber is lower than that of spandex, and the main products are polytrimethylene terephthalate (PTT) fibers and polybutylene terephthalate (PBT) fibers. Although these two kinds of fibers can be directly woven, able to meet the requirements of general textiles, due to the disadvantages of being easily deformed by heat, easy to burn, low mechanical strength, and unstable fabric shape, people turn attention to the development of two-component composite elastic fibers. The two-component composite elastic fiber is a crimped elastic fiber made of two kinds of polymers having different structures and properties, and formed into a two-component composite yarn by conjugate spinning in a certain ratio. Its elasticity is not based on the movement of hard and soft components in the molecular chain, but the difference in shrinkage or elongation of the two components in the fiber. After heat treatment, the fiber forms a spiral or wavy curl under internal stress. The crimped fibers have varying degrees of flexibility and elasticity, and their elasticity differs depending on the chemical composition, molecular structure, distribution in the fibers, and the ratio of the two components.

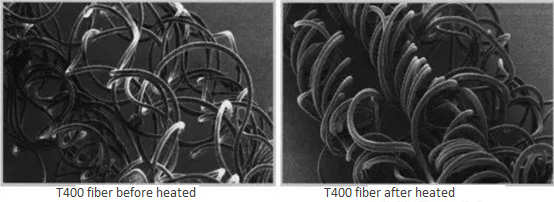

The most typical representative of two-component composite elastic fiber is DuPont's early development of "T400" fiber, which has received great attention since it is available. T400 composite fiber is a new type of elastic composite fiber, which is made by PTT and PET two-component materials, not only solving the problem of traditional spandex such as not easy to dye, excessive elasticity, complicated weaving, unstable fabric size, and easy-to-aging during use. It can be directly woven on air-jet, water-jet and rapier looms, not necessary to make into covered yarn at first like spandex before it can be weaved on the machine, which improves the quality uniformity of the product.

However, due to the limitation of the supply of one of the raw materials PTT, the price of T400 and PTT/PET fiber produced by other companies later is relatively expensive, with limited market application. Many companies at home and abroad have begun to develop PDO and PTT in the early days after seeing the development potential of this fiber and the high profit of its feedstock. Domestic companies have also cooperated with universities to develop their own production technology and put into industrial production, which is also a breakthrough in the bottleneck of PTT raw materials. At the same time, in order to solve expensive price issue of the fiber, composite elastic fiber such as SSY/SPH, T800 has also been introduced to the market, and also received a good response, enjoying sharply rising demand. For example, the hottest elastic fabric in the Shengze market this year is a T800 fabric, which effectively replaces some demand of the T400 and expands the demand field for elastic fabrics.

In general, as consumers' demands for wearing comfort continues to increase, it is believed that more and more textiles will have elasticity in the future, and in addition to spandex, polyester elastic fibers may be the most cost-effective option. From the early polyester high-elastic yarn, T400 fiber, to the current SSY/SPH, T800/T8 fiber, new polyester elastic fiber is constantly accepted and popularized by the market, and the market heat even exceeds spandex. The future demand is anticipated to possess huge growing potential.

|

|